Biodiesel from Microorganisms: Engine Performance and Exhaust Emissions

Introduction:

Biodiesel is a form of diesel fuel that is mostly produced from triglycerides (e.g., soybean oil), an alcohol (e.g., methanol), and a base or acid catalyst. Biodiesel is renewable, is generally better for the planet than other fuel, and could replace petroleum diesel fuel with minor modifications to existing engines or fuel distribution networks. Since most biodiesel is made from oilseed crops like soybeans, biodiesel is competing with food production companies and requires quality farmland. Currently there is not enough crops being grown to meet the United States’ fuel demand. However, in this study, oil producing microorganisms such as microalgae, yeast, and bacteria are being considered for producing biodiesel. The researchers studied the properties, engine performance, and emissions for biodiesel produced from the microalgae Chaetoceros gracilis, the yeast Cryptococcus curvatus, and the bacterium Rhodococcus opacus. Each biodiesel fuel produced was studied for its key physical properties and compared with commercial soybean biodiesel.

Set Up:

The fuel from each microorganism (the microalgae Chaetoceros gracilis, the yeast Cryptococcus curvatus, and the bacterium Rhodococcus opacus) operated a two-cylinder indirect injection diesel engine attached to an eddy current dynamometer, a device used for measuring power. The horsepower and torque output from the engine is reported for each microbial biofuel and compared to outputs obtained with both diesel fuel and soybean biodiesel. Key emissions data were collected for each biofuel without load at a steady 3500 rpm, allowing comparison to emissions from petroleum diesel and soybean biodiesel. Ambient temperature readings were made using an Apogee thermistor (ST-100) and surface temperatures of the engine block and eddy current brake were measured using an Apogee infrared radiometers (S1-121).Results:

Plant-based oils, commonly used to produce biodiesel are comparable in terms of fatty acid composition, containing primarily C16 and C18 fatty acids. Microbial oils, however, can differ substantially and may contain uncommon fatty acids that differ in both chain length and structure. In terms of the fatty acid chain length, biodiesel obtained from the yeast was found to be the most like soybean biodiesel with 83% of biodiesel being derived from C18 fatty acids.

A significant liability of biofuels is their higher oxygen content relative to fossil fuels, which contributes to lower energy density. As expected, the heating value per unit mass of each biodiesel fuel was lower than that of petroleum diesel (on average 15%). However, the difference in volumetric energy density of the biodiesel fuels compared to petroleum diesel reduces the difference in energy density on a per unit volume basis to 6% for soybean, 7% for microalgae, 8% for yeast, and 11% for bacteria. The difference in energy density was apparent in the power and torque outputs generated by diesel and biodiesel fuels.

Ultimately the power generated by each fuel is directly correlated to the volumetric energy density of the fuel. Fuels with greater energy density, such as diesel, had a higher power output than less energy dense fuels (e.g., bacterial biodiesel). The observed torque output for each fuel followed a similar trend with the most energy dense fuels achieving the highest torque output and the least energy dense fuels producing the least amount of torque. The power and torque output of biodiesel produced from oleaginous microbes indicate the ability of these fuels to operate as effectively as soybean biodiesel.

Conclusion:

The biodiesel produced from microorganisms can be effective fuels to replace both petroleum diesel and plant oil biodiesel. Microbial biodiesel fuels prepared from yeast, bacteria, and microalgae generated similar amounts of power and torque as compared to soybean biodiesel. All microbial and soybean biodiesel fuels had reduced hydrocarbon and CO emissions compared to petroleum diesel. This study demonstrates that microbial-derived biodiesel has comparable properties in the parameters tested to soybean biodiesel. Future wide scale use of microbial oils as a source for biodiesel will require advances in large scale cultivation, dewatering, and oil extraction.

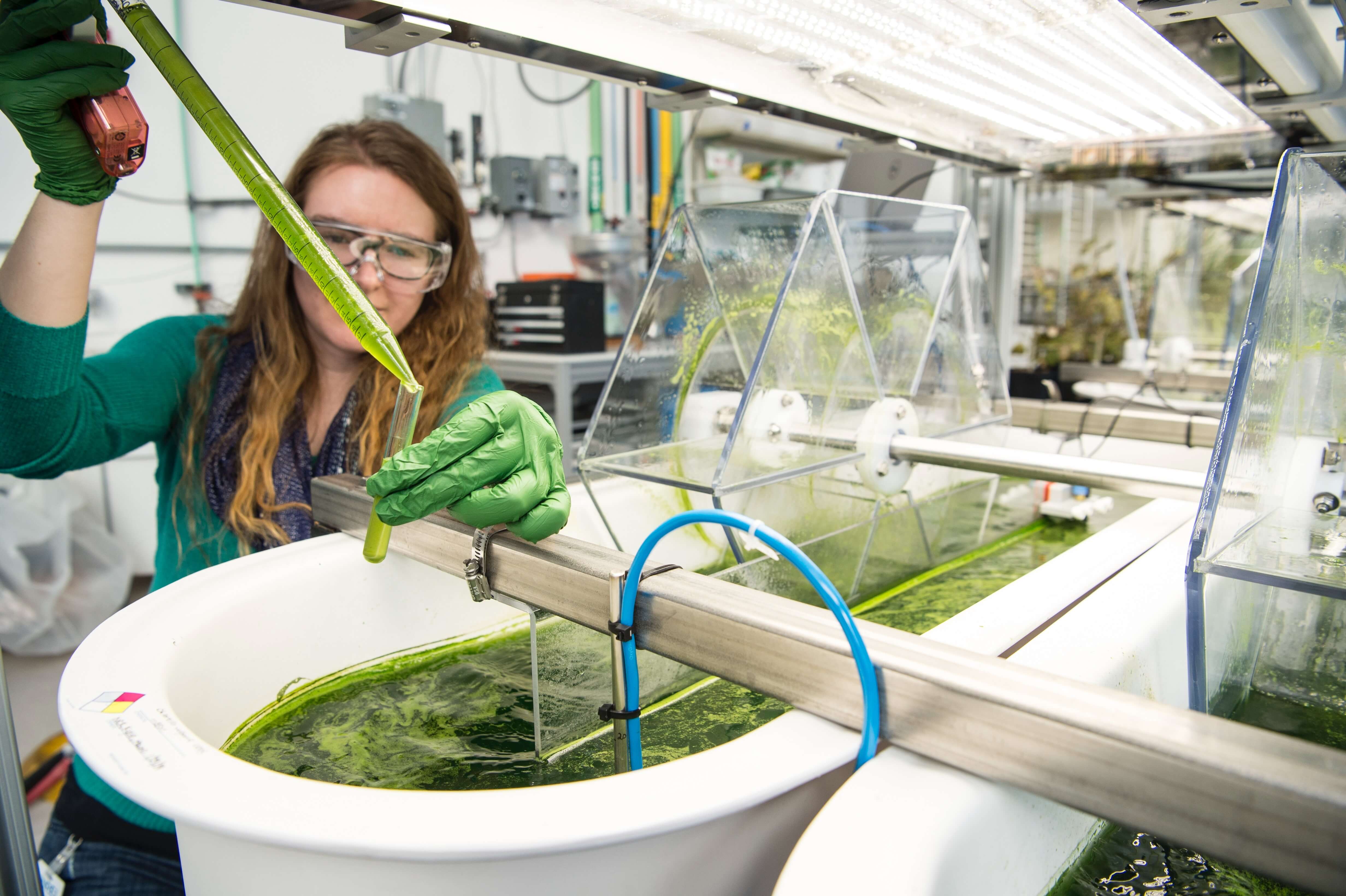

Image 2. Photo by Science in HD; Scientist taking algae samples

Image 1. Photo by Khamkéo Vilaysing; Fuel station

- Department of Chemistry and Biochemistry

- Department of Biological Engineering

- Department of Plants, Soils, and Climate

- Department of Mechanical and Aerospace Engineering

- Bradley D. Wahlen

- Michael R. Morgan

- Alex T. McCurdy

- Robert M. Willis

- Michael D. Morgan

- Daniel J. Dye

- Bruce Bugbee

- Byard D. Wood

- Lance C. Seefeldt