Sealing Layer Installations for Mine Waste

Introduction:

Large amounts of mining waste are produced in Sweden, and it can produce harmful chemicals when exposed to water, oxygen, or oxidizing bacteria. A dry cover solution consisting of a sealing and protective layer are used to stop sulfide oxidation. While the sealing layer is typically made of clay, clay availability is limited, and other alternatives are needed. In this study, the researchers tested two non-hazardous industrial wastes, green liquor dregs (GLD) and bentonite, as an effective sealing layer for mine waste, as well as two methods of installation: observation wells and pits.

Set Up:

The researchers set up observation wells and a pit containing both a GLD- and bentonite-amended till. The sealing layers were made of two different materials, a mixture of till and 10 wt.% of GLD, and a mixture of till and 4 wt.% of bentonite. A protection layer of silty till was placed over both sealing layers. Eight Apogee oxygen sensors were placed horizontally below and on top of the sealing layer. Other probes were installed by drilling holes into the observation wells.

Results:

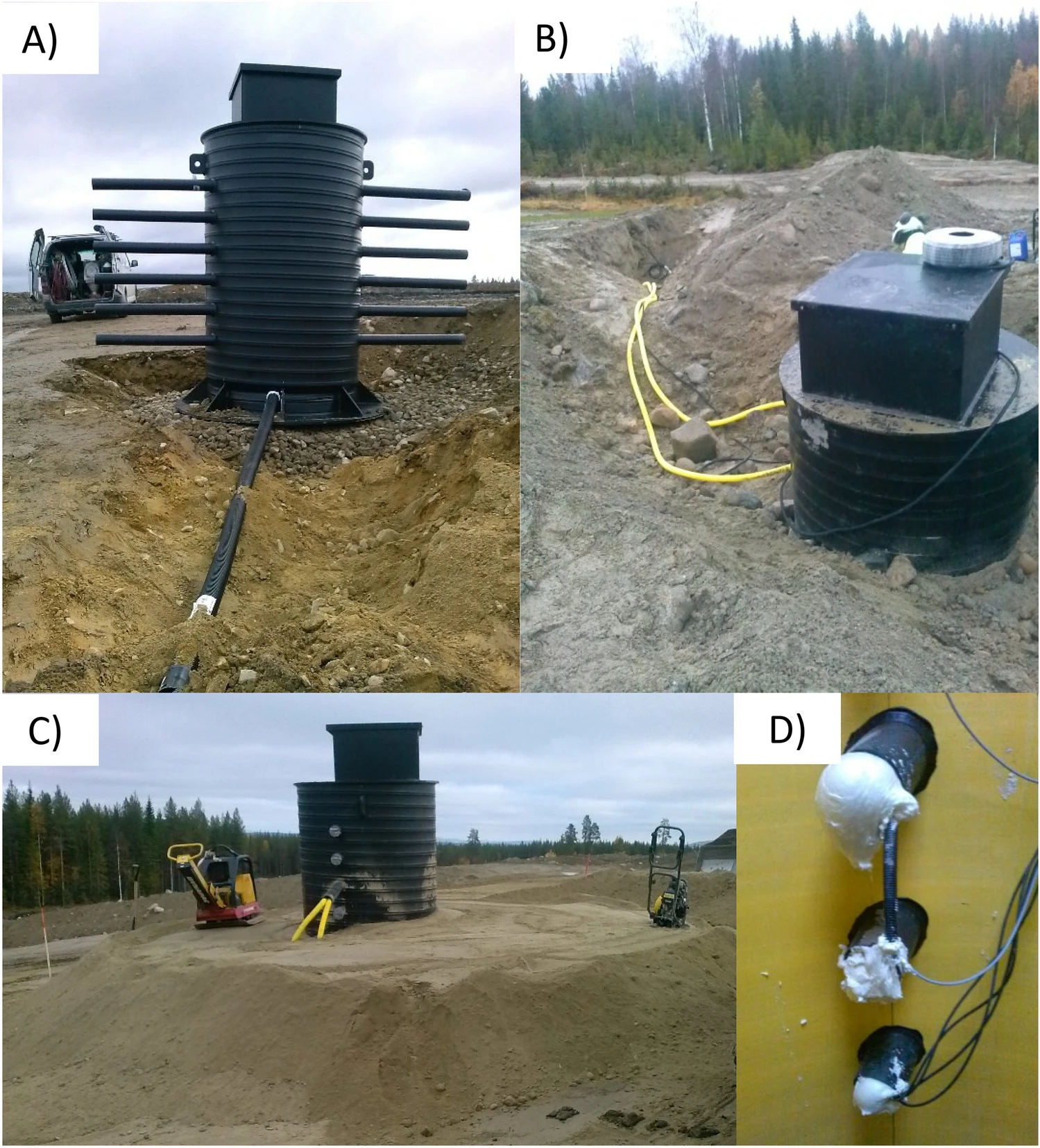

While the observation wells and pit were useful for the study, there were some issues that occurred. It was difficult to properly seal the drill holes after installing the probes in observation wells. The researchers used foam insulation and silicon to seal the holes to avoid oxygen diffusion in the wells. Another possible downside of a monitoring well is that it can act as a pathway of water and oxygen through the dry cover to the mine waste. They also found that pits are cheaper, as the only cost comes from using an excavator.

Conclusion:

Installation of instruments in a sealing layer should involve excavating a pit in the protective layer after the soil cover is installed and then drilling the probes into the sealing layer. The pit would then be backfilled, with the cables leading to the surface where the data logger is installed.

Image 2. A: A picture of one of the monitoring wells installed in the dry cover. B: One of the pits and the cables from the instruments that led to the monitoring wells. C: The hand-compacted sealing layer closest to the wells. D: The connection from the probes to the wells were insulated first with local material and then with foam insulation and silicon to keep them sealed from atmospheric influence.

Image 1. Photo by Dominik Vanyi; Heavy machinery mining for coal

- Susanne Nigéus

- Christian Maurice

- Jenny Lindblom